Report in english language

Report in english language

from Michael Anger

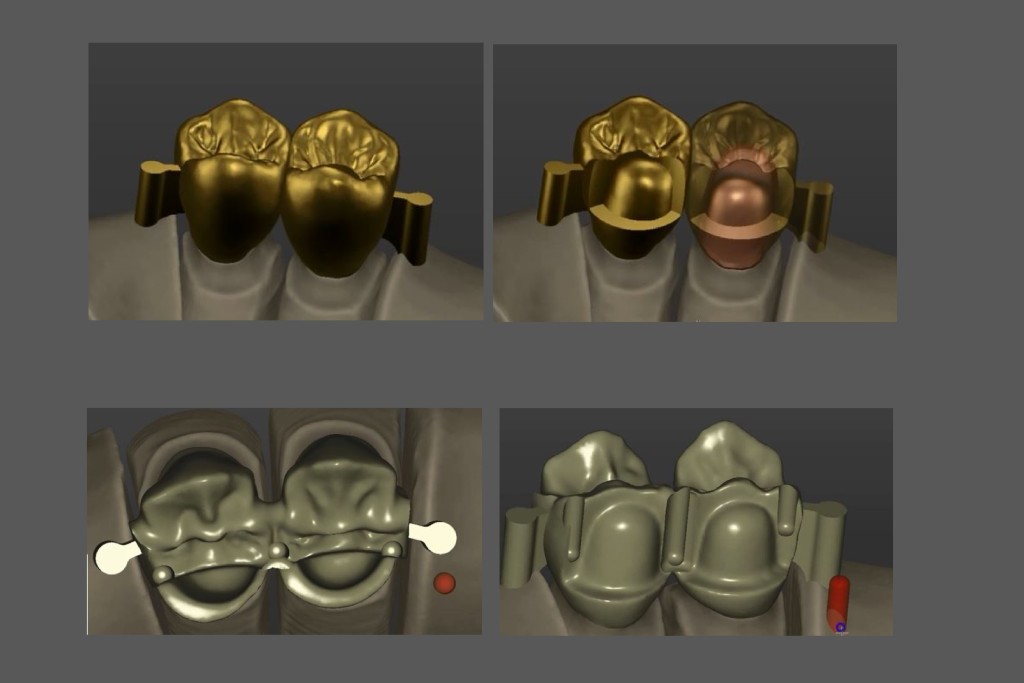

Pictures from the milling-center

Pictures from the milling-center

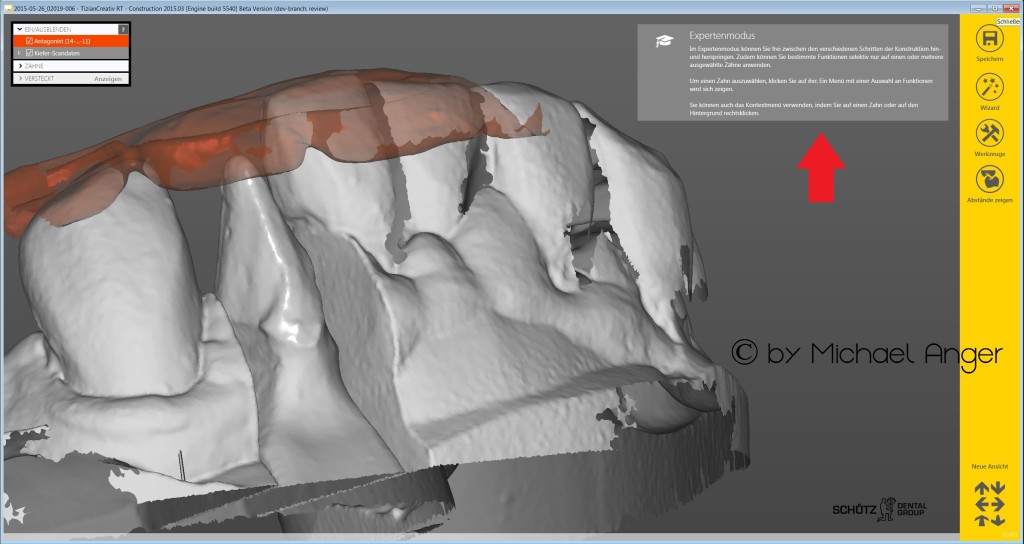

In the new Exocad software there is not only just new views, which are easier for our eyes, but also many new opportunities to easily and quickly work for the users.

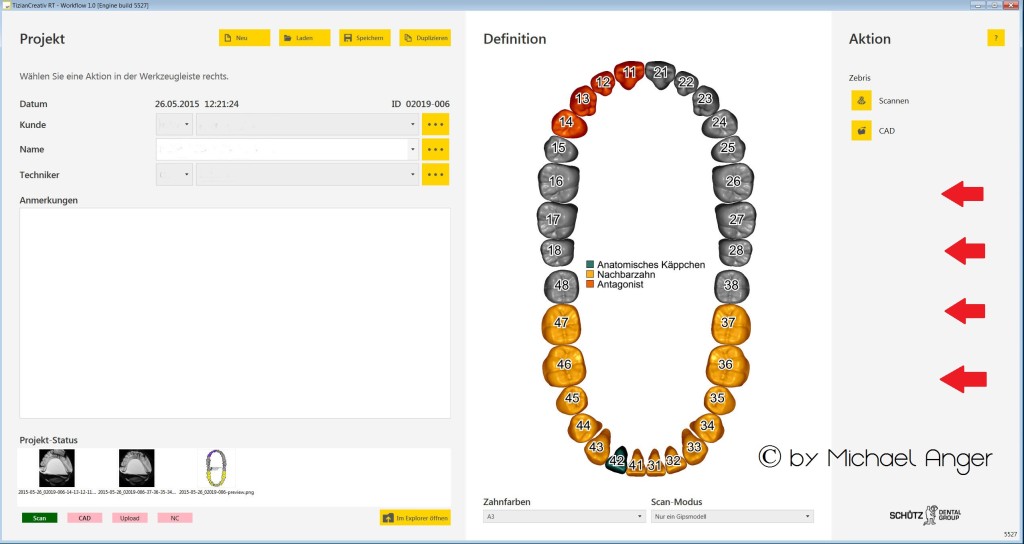

The new order list:

In this version, yet the links are missing to:

Milling centers and milling Blank-orders etc.

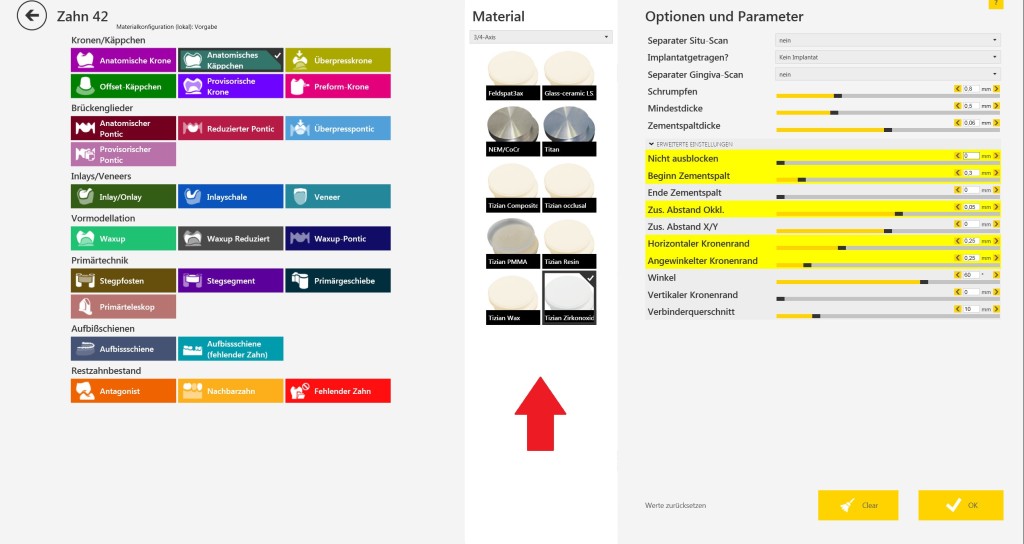

In the field for the definition of the individual teeth, we find the usual settings. The Blank selection is highlighted here also graphically and can be extended by yourself.

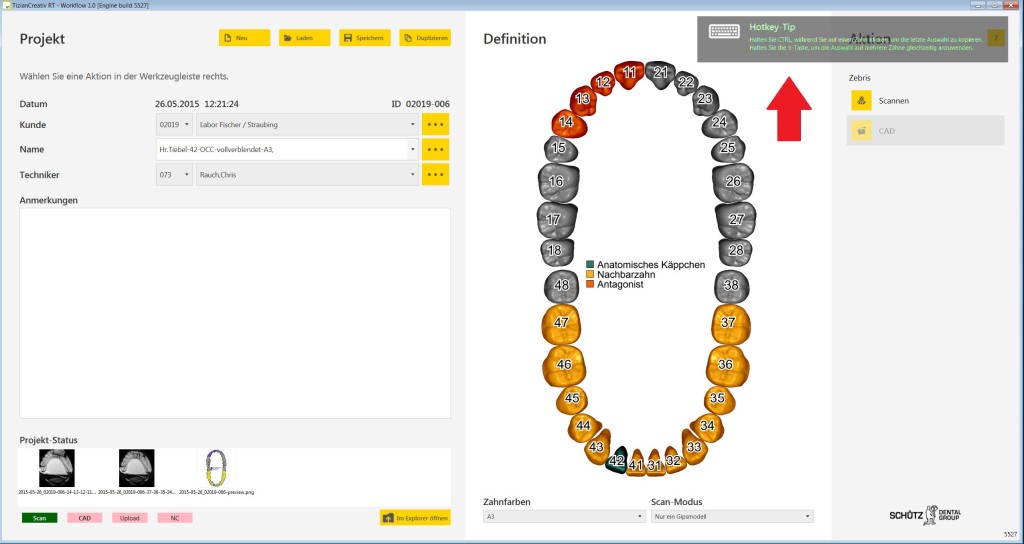

Once keyboard shortcuts would facilitate the work, the software refers to these key combinations.

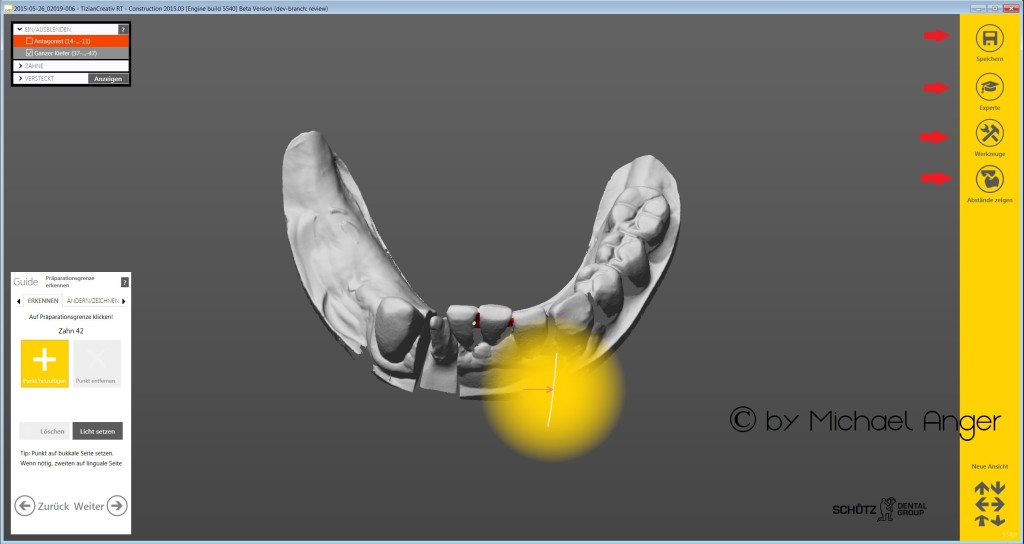

In the modeling (CAD) we find on the right the new command bar, which helps us to switch easily between the wizard and the Expert-mode.

In the expert mode are under the button „tools“ other options available than in the Wizzard. Nevertheless remain with a „right click“ on the background other tools or opportunities are hidden that are not in the „official“ tools.

Again, the software gives automaticly informations, what options the user has in the expert mode.

Changes in the scanned surfaces by „free forms„, „trimming“ or „holes close“ are here also no problem so that the modellation can be done on „clean“ files and faulty scans do not need to be renewed.

Changes in the scanned surfaces by „free forms„, „trimming“ or „holes close“ are here also no problem so that the modellation can be done on „clean“ files and faulty scans do not need to be renewed.

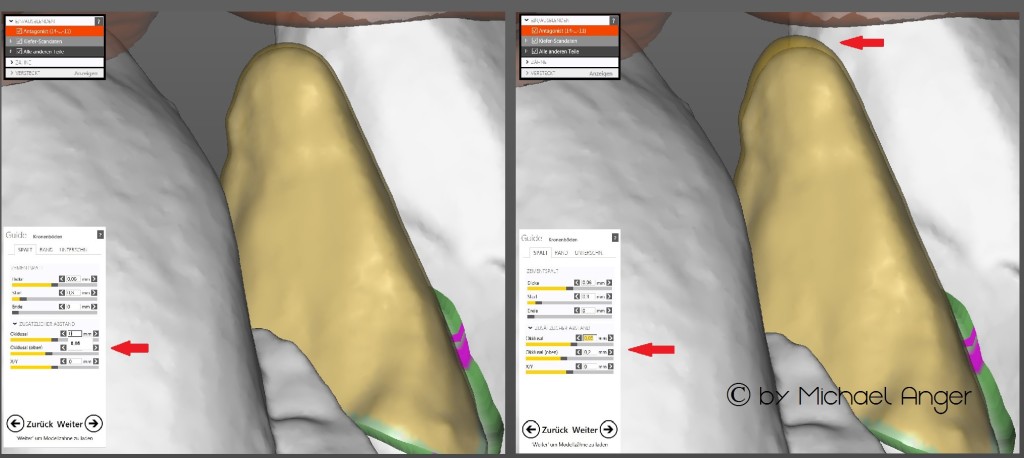

Additional can now be selected, an additional occlusal distance which applies only to the occlusal surface.

Unlike the general additional distance „occlusal“ are not changed all pointing occlusal surfaces in this setting. This deteriorated so far the fits of broad steps in the cervical area, as we find common in milled implant abutments or telescopes.

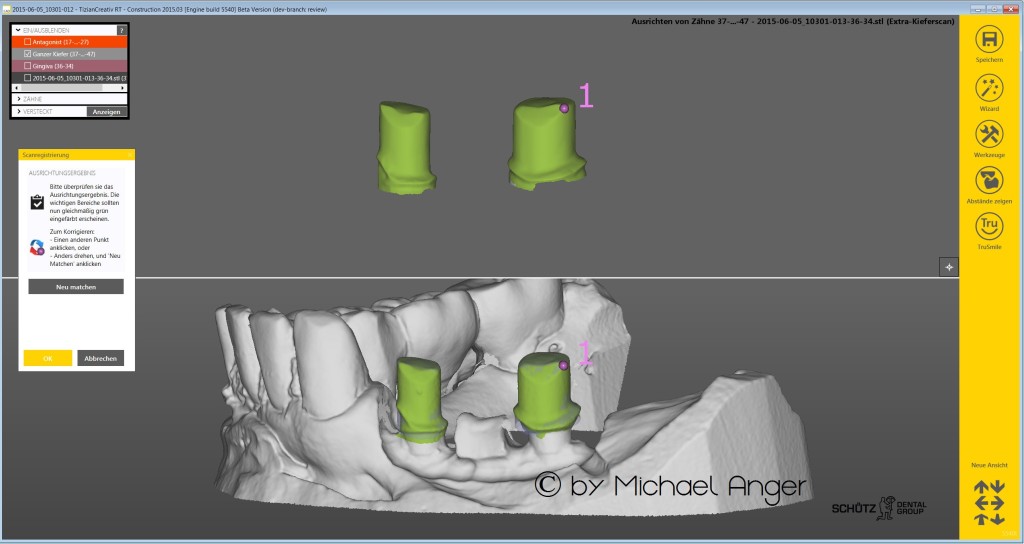

In the case of models in which the strip light scanner, could not reache some areas or in parts, which require particularly clean fits like implants or outer telescopes model segments from other scans can be matched into the main Jaw–scan. It does not matter if the scan comes from another model Scan with strip light scanner or from a tactile Renishaw scanning.

In the case of models in which the strip light scanner, could not reache some areas or in parts, which require particularly clean fits like implants or outer telescopes model segments from other scans can be matched into the main Jaw–scan. It does not matter if the scan comes from another model Scan with strip light scanner or from a tactile Renishaw scanning.

This process can be repeated as often as needed. Several parts can be matched simultaneously, this increases the precision of the transmission.

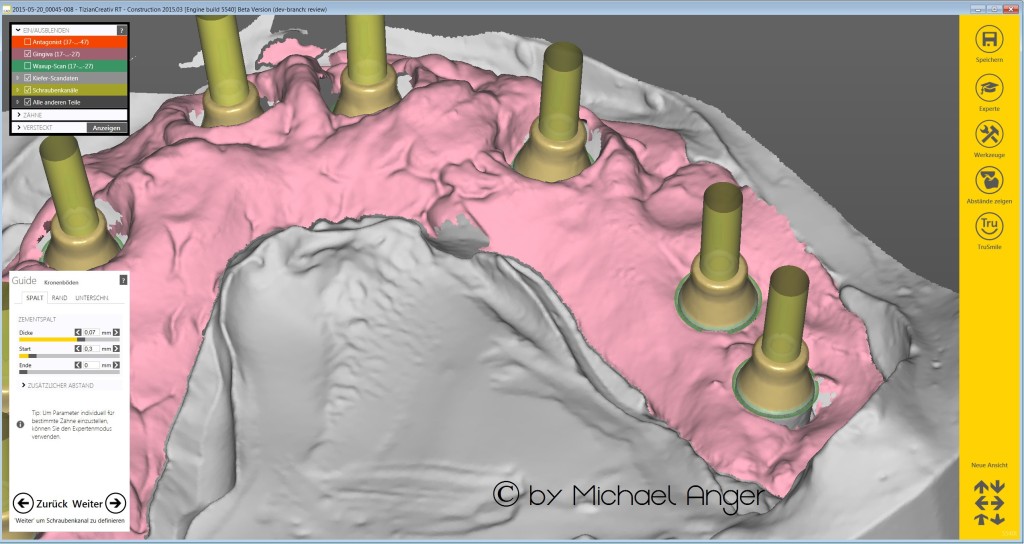

For implants, in which no scanning bodys are available, can be selected „Manual positioning„. This feature can be used for both – occlusal screwes, as well as abutments. In these cases, the diameter of the screw-channels can be determined manually and the positioning and angulation are selected case–related.

Even with the use of scann–bodys an angulation of screw channels is possible.

New views, new possibilities, new features.

Cut milled rests and interlocs out of the anatomy.

This report is still in progress….

To come to the german report click here:

Your independent e-learning & support platform!

Your independent e-learning & support platform!