After many tests and many experiments with the exocad–software and after support from the company Imes-Icore we have found new values for milling of secondary telescopes. Die ersten Ergebnisse dieser neuen Produktion stellen wir Ihnen in diesem Beitrag vor.

Tis project was supported and executed by the milling center:

For contact and more information just click on this business card.

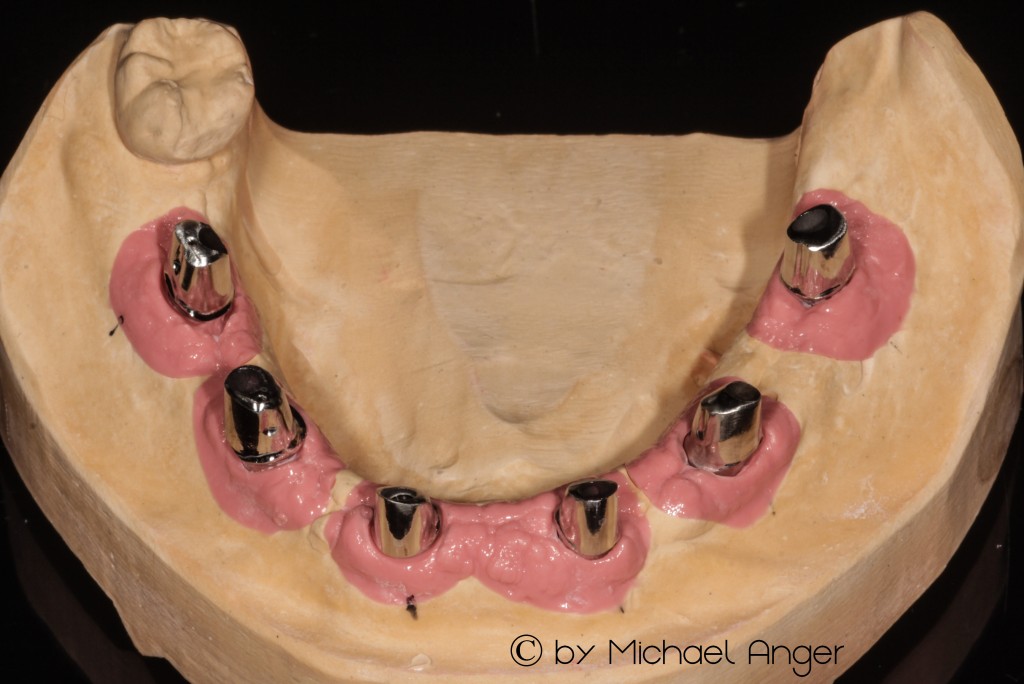

Although a 0 ° – milling is fesible in the CAD / CAM technology, but because of the extremely exact fit it is difficult to handle for the human hand.

Similarly sharp edges should be avoided at the transitions to the occlusal surfaces, as these due to the cutter radius compensation can not be machined by milling clean.

Marginal rests prevent in this cone technique an excessive drop of the tertiary structure and therefore an excessive and uncontrolled clamping action.

Despite accurate scanning technology, it is advisable to mill a single Test cap from the corresponding work as in this case, before the milling of a complete construction.

Due to temperature differences or slight changes in the machine geometry the correct values may differ.

Before removing the blank from the milling machine (550i), the individual telescopes are checked for friction back.

If necessary, individual telescopes outside this milling can be re-milled separately until the desired Ergenbis is achieved. However, the milling results are always as smooth on the inside and free of tension.

These scaffolds are never polluted by blowholes or investment inclusions and thus require only small amount of manual rework.

After separation of the retaining pins, only the friction needs to be set and the framework is completed.

Now the gained control of the friction of the total construction starts.

This framework can be stress-free set from the outset on the model and glides smoothly and loose almost to the end position.

Without pressure this construction lowers and almost falls on the primary parts.

Light, vertical ruts come exclusively through a „canting“ of work during manual removal.

Here we see the work almost in the first real friction contact. Of course we need the tactile Renishaw scanning for such results.

So far, no manual reworking was carried out on the friction surfaces here.

The customer will then finish this structure as a cover denture prosthesis and thereby use the teeth of the wax-try-in, which has been used in planning with scanned and in the construction.

More reports on this topic:

For more information and prices please contact us at:

To the overviews :

Your independent e-learning & support platform!

Your independent e-learning & support platform!