Here I start a report about a new material.

Deutsche Version :

![zzzzzflagge_deutschland_276885_by_thommy-weiss_pixeliode]()

In the near future, this material will be released and will revolutionize the dental daily work!

Because we are working with the tactile Renishaw scanner, this material is thus suitable for primary parts.

So far, the material is provided only in the Blank-form . Other dosage forms are currently unknown.

The machinability is with single-edge cutters without water cooling very well. The stability is also suitable for bar constructions.

The inner surfaces are milled clean and due to its biocompatibility, the material is very gingival friendly.

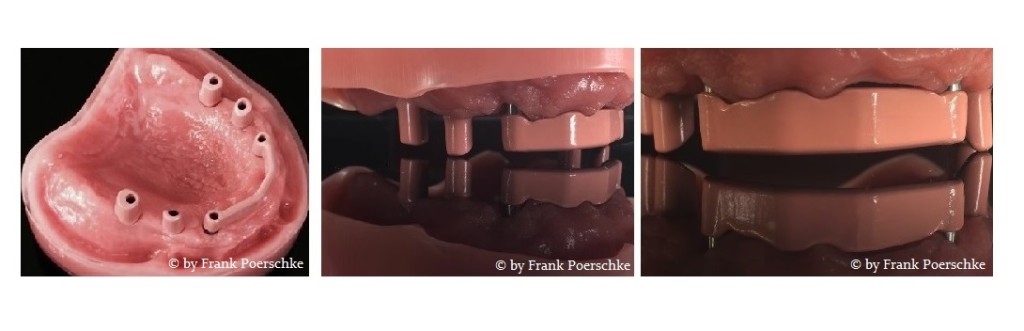

In the pictures below you will see the implant abutments after bonding to the titanium bonding bases.In this way, the perfect fit is ensured by industrially manufactured connection geometries.Screw seat and screw guide are safely housed in the titanium abutments. This technique also is called „hybrid technology“.

The polish is proving to be not so easy and requires some time, but the result is very convincing. These smooth surfaces in combination with the perfect biocompatibility is extremely gingiva-friendly. This results due to the accumulation of the gingiva an

In the case of cemented restorations the adhesive surface should be illuminated with corundum and additionally bonderized. Cementation should be made in this case with dual cement.

The bond should be free of gaps and the transitions are polished together.

The metal surfaces are also radiated with corundum and conditioned with metal primers.

For gluing clear Panavia is used so that the transitions are not visible.

The surfaces are refined after rough–milled with cross-cut-drills and fine milling with single-edged-cutters with fine sandpaper.

The transitions and the stages are worked out with abrasive gum-polishers and then polished with goats-hair–brushes and wool-buffs.

As polishing paste „Dialog–Vario–Polish“ is used.

This demo models we have made in the customer order to be able to simulate strong bends of the implant axes. In case of implants, always is spoken about the

For the scanning for the secondary structure with the tactile Renishaw scanner, either a generously sized, removable gingiva should be made or a scan model is needed. The tactile needle of the scanner must pass safely under the shoulders of the primary parts. Likewise, under the basal edge of the bar.

Here the first image of the secondary structure

Here are some pictures for tactile scanning with the Renishaw scanner.

To enable such scans we mostly perform a scan model.

Here, the stumps are transferred position-exactly on a gypsum base to grant the tactile needle free access.

By using the best technology, we achieve with this material a soft, sliding friction from the first contact.Patienten und Zahnärzte, die einmal eine solche Arbeit bekommen haben sind begeistert und verlangen immer wieder danach.

Perfect telescoping work here are easy for anyone to produce. The weight is much lower than in metal and when the patient looks at the basal of his denture, he sees only the pink cap in the pink denture-plastic is of the saddle.

The following figures show the transitions from primary to secondary crowns, and the adhesive joints are recognizable.

In order to refine all transitions are polished together after assembly.

Here are some pictures of colleague Frank Poerschke, which is also engaged in the first test works of this material.

These pictures received my message yesterday evening and are only the first images by the phone.

First material testing and physical values:

Bending strength after DIN EN ISO 10477 : 220 MPa

Bending strength after DIN EN ISO 20795-1 : 170 MPa

Bending modulus after DIN EN ISO 20795-1 : 4500 Mpa

Further technical datas are unfortunately not available yet and be submitted as soon as possible.

This new PEEK in the color pink is offered by the company Merz Dental, which has kindly allowed me, to present these images and descriptions beforehand.

Link to Merz :

![zz Merz]()

Zurück zur Übersicht

Your independent e-learning & support platform!

Your independent e-learning & support platform!